It is suitable for extreme environments such as high temperature, high pres

Service Hotline :

+8618613619129

It is suitable for extreme environments such as high temperature, high pressure, strong corrosion and high wear in chemical, petroleum, pharmaceutical, metallurgical and other industries. Its excellent heat exchange efficiency can meet the urgent needs of energy saving, emission reduction and environmental protection.

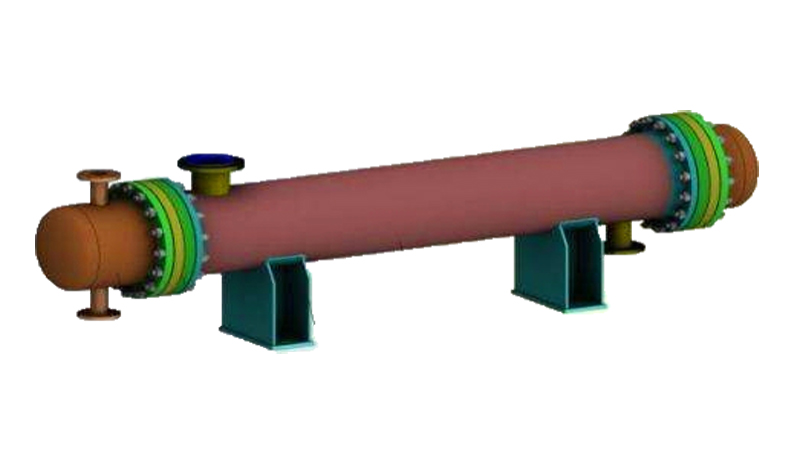

Structure:The structure of silicon carbide tube and tube heat exchanger is the same as other tube and tube heat exchangers. It is composed of shell, silicon carbide heat exchange tube bundle, tube box (head), baffle plate, tube plate, seal, takeover, etc. The structure is simple and compact, and the cost is low.

Principle:The sealing of silicon carbide heat exchanger tubes is based on a double-sealed O-ring system on both sides of the tube. The double tube plate design makes it possible to use a separate chamber to separate the process fluid and the working fluid, so that when the O-ring system is damaged or leaks, there will be no mixing between the two fluids. The housing chamber can be pressurized at a higher pressure than a single seal system to avoid leakage from the O-ring system.

Performance:Silicon carbide is a single-phase, pressureless sintered, high-purity, fine-grained and extremely low-porosity engineering ceramic. It has excellent properties such as corrosion resistance, high temperature resistance, high thermal conductivity, high hardness and wear resistance. Sex. It can be used as an excellent substitute for traditional corrosion-resistant materials such as graphite, stainless steel, precious metals titanium, tantalum, Hastelloy, and fluoroplastics.

Shell material:Silicon carbide heat exchangers can be specifically designed for various applications. Appropriate components will be assembled according to the characteristics of the specific medium. According to the anti-corrosion requirements, the shell material can use carbon steel, stainless steel, lined with PTFE, glass lined, corrosion-resistant precious metals, alloy materials, etc.

Product advantages:

① High thermal conductivity -The thermal conductivity of silicon carbide is much higher than other corrosion-resistant materials. When used as a heat transfer element in a heat exchanger, less heat exchange area is used with the same heat transfer efficiency, allowing a smaller size and reducing the space occupied.

② Excellent corrosion resistance -Silicon carbide materials have extremely high corrosion resistance, oxidation resistance and corrosion resistance, and are suitable for high concentrations of sulfuric acid, nitric acid, phosphoric acid, mixed acids, strong alkalis, oxidants, etc. It is the only anticorrosive ceramic material that is resistant to hydrofluoric acid.

③ Excellent thermodynamic properties -Silicon carbide is a hexagonal crystal with a specific gravity of 3.20-3.25 and a microhardness of 2840-3320 kg/mm². It has the characteristics of stable chemical properties, high thermal conductivity, low thermal expansion coefficient, high hardness, high strength, light weight and long service life. It has excellent wear resistance and permeability resistance under extreme high temperature and high pressure conditions. The silicon carbide tube allows the medium to pass through at high speed.

④ Antistatic - Silicon carbide is conductive and does not accumulate static electricity.